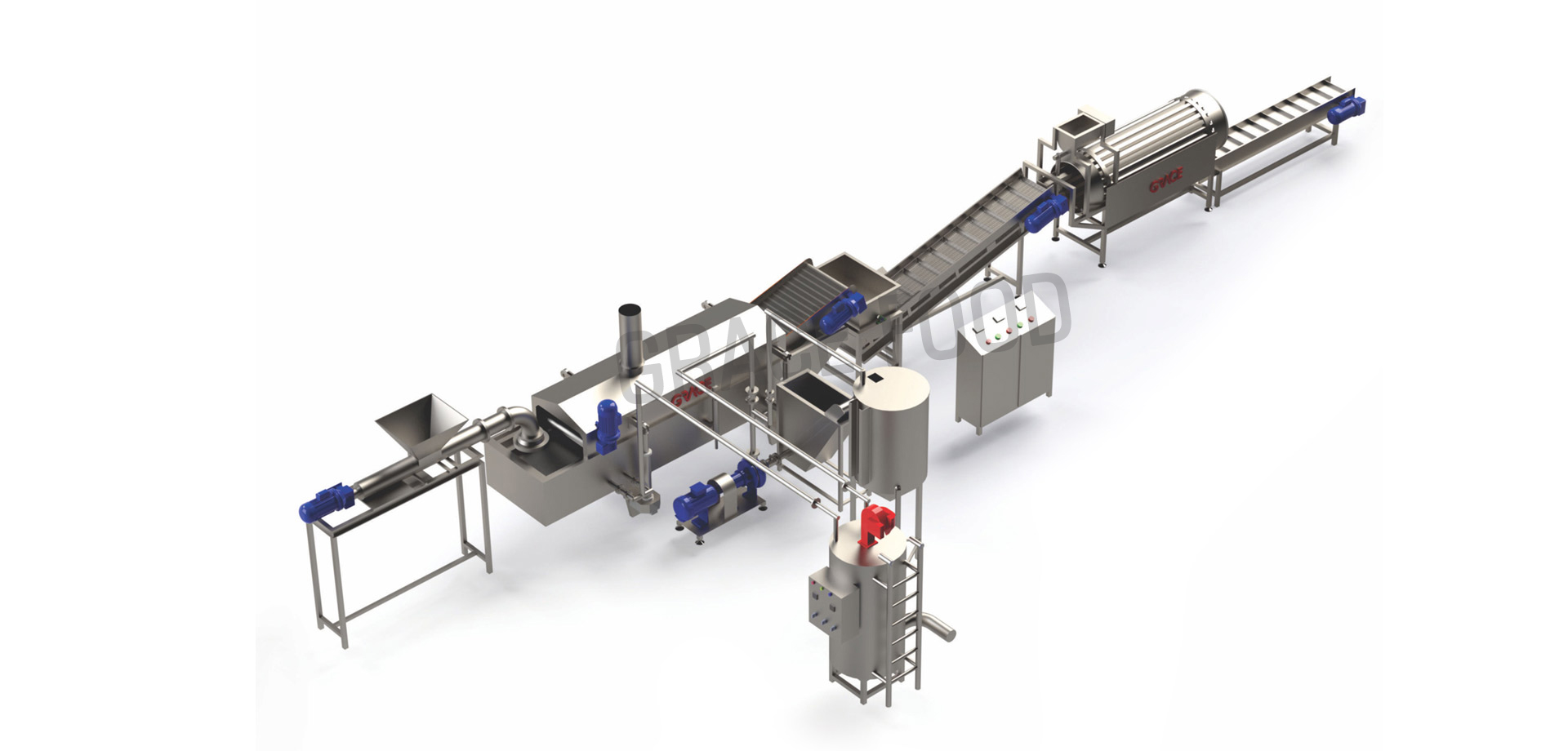

Green Peas Frying Line

Green Peas is fried from our production line to make crispy and tasty snacks.

Technical Specifications

| Model | GTL-150-GPL | GTL-300-GPL | GTL-500-BCL |

|---|---|---|---|

| Output | 150 kg/hr | 300 kg/hr | 500 kg/hr |

| Power Required | 30 HP approx. | 45 HP approx. | 55 HP approx. |

| Floor Space | 1500 Sq. ft. | 2000 Sq. ft. | 4000 Sq. ft. |

| Material of construction | AISS-304 Grade SS | AISS-304 Grade SS | AISS-304 Grade SS |

| Oil Heating Fuel Option | Diesel or Gas | Diesel or Gas | Diesel or Gas |

Soaking

Depending on the variety, green beans must be immersed in clear water and food dye 8-12 hours before production, and at the same time screen out the beans with poor selling and appearance, ensuring the quality of the basic raw materials to increase the taste of green beans. After soaking, raw material Green Pea is put into the Frying Green Pea Production Line.

Excess water removal

Round and elongated cut are done, precise thickness, high production capacity, comparative low maintenance

Frying System

In the stage of water draining, it is necessary to remove the excess water of the Green Pea to prevent affecting the quality of the finished pea and oil due to too much moisture, and to prevent the burst of the pea. We offer dehydration equipment to ensure that the speed and capacity of water draining can be adjusted according to the requirements of the production without injuring the quality of Green Pea.

Screening Machine

The Frying Green Pea Production Line of Grace Machinery is equipped with continuous screening equipment. According to the customer's needs, it can automatically and continuously select the green beans of different sizes according to the specific size of the sieve mesh, so that the size of the product can be easily controlled. Maintain quality and reduce differentiation of the product.

Pre- Fryer

A pre-fryer is used to remove the extra moisture from the pellet in order to increase the shelf life and reduce the frying time

Frying System

The frying equipment has the added value of energy saving, space saving, oil saving, and high heat exchange rate and recovery rate. The fully automatic control system saves the time for personnel to operate, and also keeps the oil temperature at a certain temperature during the frying process, and ensures the first-in-first-out of the product through the continuous mesh belt to prevent material accumulation. Because of the frying temperature required for fried Green Pea can’t be too high, to prevent the burst of the pea. In addition to convenient subsequent seasoning and packaging process, it also maintains the quality of Green Pea in the production process and the taste after production.

Continuous Oil Filter

While continuous frying operation the oil gets fines released from the product, which degrades the oil quality, in-order to remove those fines we use highly effective oil filtration system designed.

De-oilingr

The de-oiling machine of the Frying Green Pea Production Line uses centrifugal de-oiling method, and adjusts the speed and capacity according to the customer's needs to remove excess oil. At the same time, the de-oiling machine has the characteristics of simple maintenance and cleaning, which reduces the time cost in the continuous production process, thereby improving production efficiency.

Sprinkling & Seasoning system

The sprinkling and seasoning equipment which can control the seasoning time and sprinkling amount. Customers can adjust the equipment at any time according to the production demand. Green Peas need a coating to become tasty, this is done in a coating drum immediately after frying and de-oiling. The coating drum comes in various sizes and has on the inside a self-cleaning profile. To ensure uniform residence time, strips are mounted in the drum. The rotation speed of drum are variable.